Relied On Industrial Scales Brands Advised by Specialists

Exactly How Commercial Scales Improve Precision in Manufacturing and Logistics

By making sure that products are evaluated properly, companies can minimize mistakes that could lead to considerable financial consequences. The advent of innovative innovations in evaluating systems is transforming conventional processes.

Relevance of Precision in Workflow

In the world of manufacturing and logistics, precision is the cornerstone of operational efficiency. Exact measurements are essential for maintaining quality assurance, optimizing resource allotment, and ensuring compliance with sector criteria. When procedures rely upon exact data, services can minimize waste, enhance manufacturing timelines, and boost overall productivity.

The relevance of precision prolongs past straightforward measurement; it also affects decision-making procedures. As an example, accurate weight analyses can identify proper supply levels, streamline supply chain logistics, and assist in precise invoicing. Mistakes in measurements can lead to pricey errors, such as overflow or underestimating material demands, which can jeopardize task timelines and productivity.

By implementing strenuous measurement standards, organizations can identify inefficiencies and pass enhancements, inevitably leading to improved client satisfaction. Hence, investing in precision dimension devices, such as commercial scales, is not just a technological consideration however a tactical imperative for success in the production and logistics sectors.

Kinds of Industrial Scales

Different kinds of commercial ranges play an essential duty in achieving the accuracy necessary for effective manufacturing and logistics procedures. Each kind is developed to fulfill details demands, ensuring precise dimension of items, materials, and elements.

One common kind is the system scale, which gives a level surface area for evaluating big products or bulk materials. These ranges are commonly used in warehouses and delivery centers. An additional type is the bench range, normally smaller and used for considering individual packages or smaller batches of products. These ranges are necessary in quality assurance procedures. Industrial Scales.

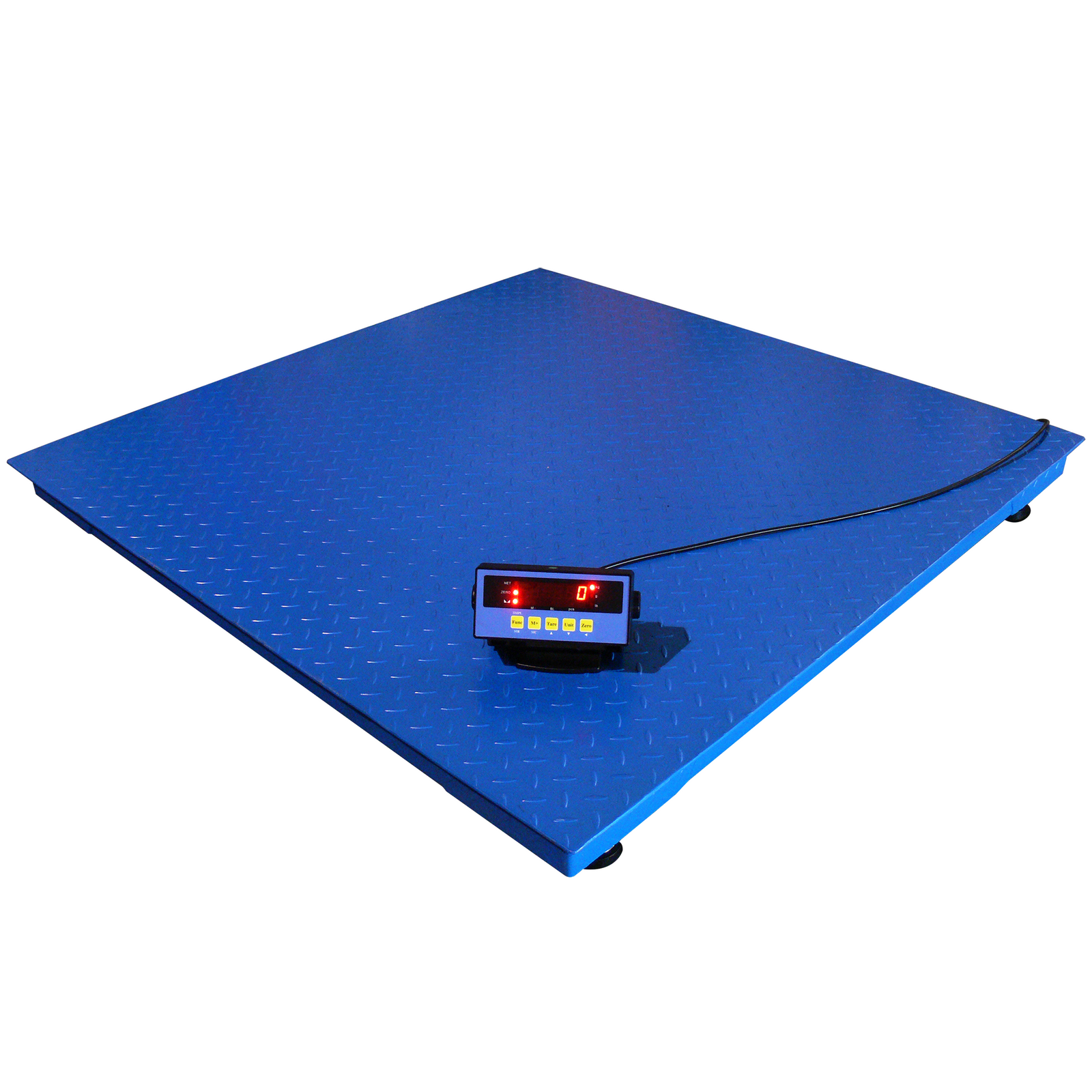

For applications where accuracy is essential, logical balances are utilized. These high-accuracy ranges are utilized in labs and study setups to measure little amounts with utmost precision. Floor scales, designed for heavy-duty evaluating, are optimal for considering large pallets or containers, commonly integrated with forklifts for efficiency.

In enhancement, lots cells are utilized in numerous applications for real-time weight dimension and data collection. Each of these scales contributes distinctly to the operational efficiency, making sure that businesses can maintain precision throughout their manufacturing and logistics procedures. Recognizing the types of industrial scales is essential for enhancing efficiency and accomplishing functional excellence.

Effect on Stock Administration

Precise evaluating is vital for efficient stock management, as it straight affects supply accuracy and functional efficiency. In production and logistics, specific measurement of items and materials guarantees that supply records mirror actual stock degrees, lowering disparities that can bring about overstocking or stockouts. Industrial scales give the necessary accuracy to consider things precisely, enabling businesses to keep a trusted stock system.

Furthermore, accurate evaluating adds to better forecasting and planning. With exact information on stock degrees, companies can make enlightened decisions concerning purchase and production schedules. This minimizes the threat of excess inventory, which can bind funding and boost storage expenses, in addition to avoid scarcities that might disrupt operations.

Additionally, the combination of industrial ranges with stock monitoring systems assists in real-time monitoring of stock movements. This streamlines the procedure of upgrading inventory records, enhancing openness and responsibility throughout the supply chain. Eventually, accurate weighing not just sustains efficient inventory administration but likewise drives total functional efficiency, making it possible for organizations to react promptly to market needs and maintain an one-upmanship in their respective markets.

Enhancing Quality Assurance

Effective inventory monitoring not just guarantees ideal supply degrees yet additionally lays the groundwork for durable top quality control procedures. Industrial scales play a pivotal function in boosting quality assurance by supplying precise weight measurements that are crucial for keeping item honesty. Regular weight verification allows makers to follow specs, making sure that each thing satisfies the necessary high quality view it now standards.

In high-stakes environments, such as food manufacturing or drugs, also minor weight disparities can cause considerable conformity problems. By integrating industrial scales right into the production line, business can keep track of product weights in genuine time, permitting prompt corrective activities if abnormalities are discovered. This aggressive strategy minimizes waste and improves overall item integrity.

Moreover, precise considering promotes far better solution of resources, which is critical in industries such as chemicals and cosmetics. By ensuring that ingredient ratios remain consistent, makers can attain superior item top quality, boosting consumer contentment and reducing returns.

Future Fads in Evaluating Technology

The future of considering innovation is poised for considerable innovations driven by automation, connectivity, and information analytics. As industries develop, the assimilation of advanced sensing units and IoT (Internet of Points) capacities will allow real-time monitoring and coverage of weight information. This connectivity will not only improve functional efficiency however also promote anticipating maintenance, lowering downtime and improving useful source efficiency.

Moreover, the consolidation of expert system and maker knowing algorithms into evaluating systems will certainly boost data evaluation abilities. These innovations can determine abnormalities and patterns, enabling even more enlightened decision-making and maximized supply chain monitoring. Moreover, the increase of cloud-based options will allow seamless information sharing across systems, ensuring that stakeholders have accessibility to updated information in all times.

Sustainability will certainly likewise play an important duty in future evaluating technology. As organizations aim to minimize their carbon footprint, considering systems that include energy-efficient designs and materials will come to be progressively important. Additionally, innovations in electronic evaluating ranges will support better resource administration by providing exact measurements that decrease waste.

Final Thought

To conclude, commercial scales dramatically improve precision in production sites and logistics by giving accurate weight dimensions vital for efficient operations. Their role in supply monitoring, quality assurance, and combination with sophisticated innovations highlights their importance in enhancing and lessening inconsistencies source allotment. As markets remain to evolve, the fostering of ingenious considering solutions will even more support functional performance and decrease waste, ultimately adding to improved performance and competition out there.

One common type is the platform scale, which supplies a flat surface for evaluating bulk products or large things. An additional type is the bench range, generally smaller sized and used for weighing individual plans or smaller sized batches of products. Floor ranges, developed for heavy-duty weighing, are perfect for considering big pallets or containers, frequently incorporated with forklifts for performance.

Industrial scales provide the essential precision to consider items properly, allowing organizations to maintain a reliable stock system.